SERVING THE ENTIRE WASHINGTON, D.C. AREA

If you live in Washington, DC and you want to transform your garage into a spotless and clean environment, Garage Design Source offers the best garage floor coatings.

Choosing the right coatings for garage floor sometimes can cause a terrible headache if you choose the wrong epoxy or paint. Epoxy floor systems sound like a good idea, but our professionals in DC always warmly recommend polyurea or polyaspartic floor for a garage. In this epoxy vs polyurea battle, the second choice wins since refinishing the garage floor with polyurea can bring only the superior results. Avoid scratches and stains, or if you already have them don‘t ignore them! Our reliable team in Washington offers you 4x stronger alternative to epoxy. It’s highly flexible, environmentally friendly and easy to install. All products that Garage Design Source in D.C. offers have unique characteristic. But in the last few years, polyurea and polyaspartic products have overshadowed epoxy in the garage flooring industry.

What are the pre-installation and installation process steps?

Garage Design Source provides a polyurea multi-coat flooring system which represents the latest advancement in concrete coating technology that is much different than traditional epoxy floor system. In order to provide the customer with the strongest warranty in the industry, we will install the coating after all of the following issues are resolved.

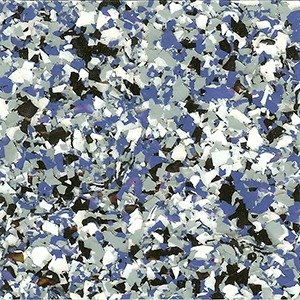

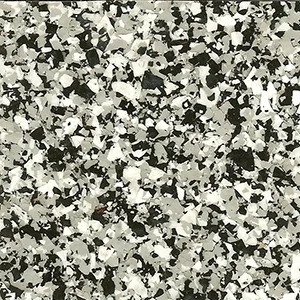

Remember, choosing a right color and design that will match your residential, commercial or industrial space in DC is also important part of pre-installation process. This is probably the most exciting part of the process for our customers, because our goal is to make your epoxy and polyurea floor coatings look both strong and beautiful.

Garage Floor Coatings – Step by Step and what to expect?

Installation Assessment

Our professional team in DC will assess the conditions of the floor and attempt to determine whether there are any concrete moisture, cracks, oil or other contaminants present in the floor that will require special treatment.

Crack Repair

Many homes have some minor or major concrete slab cracks. Garage Design Source uses the most advanced crack repair technology. We will carefully fill in all the cracks, camouflage holes, remove the stains if your old concrete shows any signs of damage.

Concrete Preparation

In order for the polyurea of epoxy floor coating to properly bond with the concrete surface, our team will use the top quality polyurea garage floor kit to make the best possible preparation before the installation process. Acid etching, diamond grinding or pressure washing will open the pores for better penetration of the solution.

Testing

Before the epoxy or polyurea floor coating takes place, Garage Design Source experts will do the testing to see if there‘s a proper chemical reaction occurring. The type of surface and the ability of it to flow in will greatly affect the bonding process.

Stem Wall & Cove Base

Among the many things that help make our polyurea floor coating unique is its ability to be installed on horizontal as well as vertical surfaces. Through the use of a fast curing and easy to apply product that has the same zero-odor, zero-VOC qualities, we can mold a “coved” base finish in the corners where the wall meets the floor, creating a neat and easy to maintain edge.

Prime Coat

First, we apply the base coat. The first coat of the floor coating acts as the primer and it takes an hour to cure. Garage Design Source in DC does not recommend the primer to be the only coating, unless you apply it on a smaller surface that‘s not exposed to pressure and wear.

Final Coats

After the curing process is completed the top coat with chips or quartz can be applied. This top coat enables anti-slip properties of the coating, This coating is optional, but it‘s highly recommended. The third coat is a garage floor clear coat that is also optional. However, its high gloss finish will make the floor look elegant and luxurious.

What are polyurea and polyaspartic garage floor coatings?

Unlike epoxy coatings, polyurea provides the perfect solution to every concrete problem your garage may encounter. It is created to withstand a multitude of damaging factors like oils, chemicals, abrasion, heat, heavy loads etc. It appeared on the market recently and very soon became popular in Washington DC among installers as an improved version of epoxy. Polyurea and polyaspartics belong to a group of polyurethanes whose components enable fast curing and hardening. Garage Design Source experts In Washington D.C. guarantee that they have no VOCs. However, due to their fast hardening properties, they must be applied by a professional. Check out why thousands of clients gave us a vote of confidence! If you‘re looking for detail-oriented information, measurements or samples – don‘t waste your time, call our professional garage contractor in DC today!

Polyurea Facts

| Garage Designe Source | Epoxy | |

|---|---|---|

| Durability | 4x stronger | |

| Flexibility | 98% more | |

| Vehicle Traffic | 24 hours | 3 days |

| Installation | 1 day | 2-3 days |

| Scratch Resistant | 3x more | |

| UV Stable | yes | no |

| Odor | no | yes |

| Wooden Step Application | yes | no |

| Warranty | Yes | 0 |

| Year Round Installation | yes | no |

What are the most important benefits of polyurea garage floor coatings?

Garage Design Source in D.C. refers to polyurea garage floor coating as the ‘holy grail‘ of garage floor coatings since it has many beneficial properties. The most important are temperature and time.

- This kind of garage surfacing can be applied in almost all weather conditions, including very high and low temperatures. Epoxy coatings are not one-day coating systems, and they require ideal temperatures and impose limitations. However, polyurea floor coatings can be applied in temperatures reaching -30 C or +60 C. Our professionals from Washington underline that you don‘t have to wait for ideal weather conditions to fix your garage floor.

- We know that epoxy coating systems are strong and fast curing. But rock solid polyurea garage floor coatings will become strong in 1-2 hours and ready for use the following day. You don‘t have to wait 3-5 days like you used to with epoxy. Garage Design Source knows that time is money, and the cure speed faster than epoxy stands out as the most important benefit. It takes only one-day garage installation to get a super strong and super resistant floor surface that any customer will simply adore!

- Customers agree that one-day installation is a fantastic thing. Make sure that the proper mixing and installation process is done by a professional company if you want your floor in Washington to withstand the test of time. If you compare the benefits of polyaspartic floor coating vs epoxy, keep in mind that the first one is priced little higher. We guarantee that the additional expense is worth every cent.

Schedule a FREE Consultation Today

Call Garage Design Source in Washington, D.C. today! We‘ll help you choose the best color and design for your garage and make you fall in love with your new high quality, elegant floor. Forget about the epoxy coating, our polyurea floor coating will beautify and protect your garage space well beyond your expectations!

Garage Design Source has been helping Washington, D.C. home and business owners beautify their floors and organize their homes and offices for 13 years. With thousands of happy customers throughout the greater Washington, D.C. region, you can have peace of mind knowing that you are working with one of the area’s most respected home services contractor.

Schedule a no-hassle in-home consultation today and see what the Garage Design Source magic is all about!